Thermoelectric materials are unique because they can directly convert waste heat into electricity. This means they can harvest energy that would otherwise be lost.

Applications are wide-ranging:

- Automotive: recovering heat from exhaust systems to power onboard electronics.

- Industrial: capturing heat from steelmaking, glass, or chemical plants to reduce energy waste.

- Space exploration: powering spacecraft with radioisotope thermoelectric generators (RTGs) where solar power is not possible.

- Wearables & IoT: using body heat to drive small sensors or devices without batteries.

Germanium telluride (GeTe)

Among these materials, germanium telluride (GeTe) stands out as a leading candidate. GeTe is attractive because it operates efficiently near room temperature and is made from relatively abundant elements. However, its performance is tied to a structural phase transition: GeTe naturally switches from a rhombohedral to a cubic crystal structure just above room temperature. This transition strongly affects how heat and charge carriers move through the material, which in turn determines its thermoelectric efficiency.

The recent study “Orchestrating phase transition in GeTe thermoelectrics: An investigation into the role of electronegativity” demonstrates that the electronegativity difference (Δχ) between cations and anions can be used as a design principle to control this structural transition. By alloying GeTe with AgInTe₂ and adding Sb to improve solubility, researchers successfully stabilized the cubic phase at room temperature.

This chemical tuning led to several benefits:

- A higher electronic density of states, which improves electrical performance,

- A reduction in lattice thermal conductivity, which minimizes heat loss,

- And a peak thermoelectric figure of merit (zT) of 1.01 at 473 K.

These improvements enabled a single-leg device with up to 9.2% energy-conversion efficiency at a 500 K temperature gradient—an important milestone toward practical thermoelectric applications.

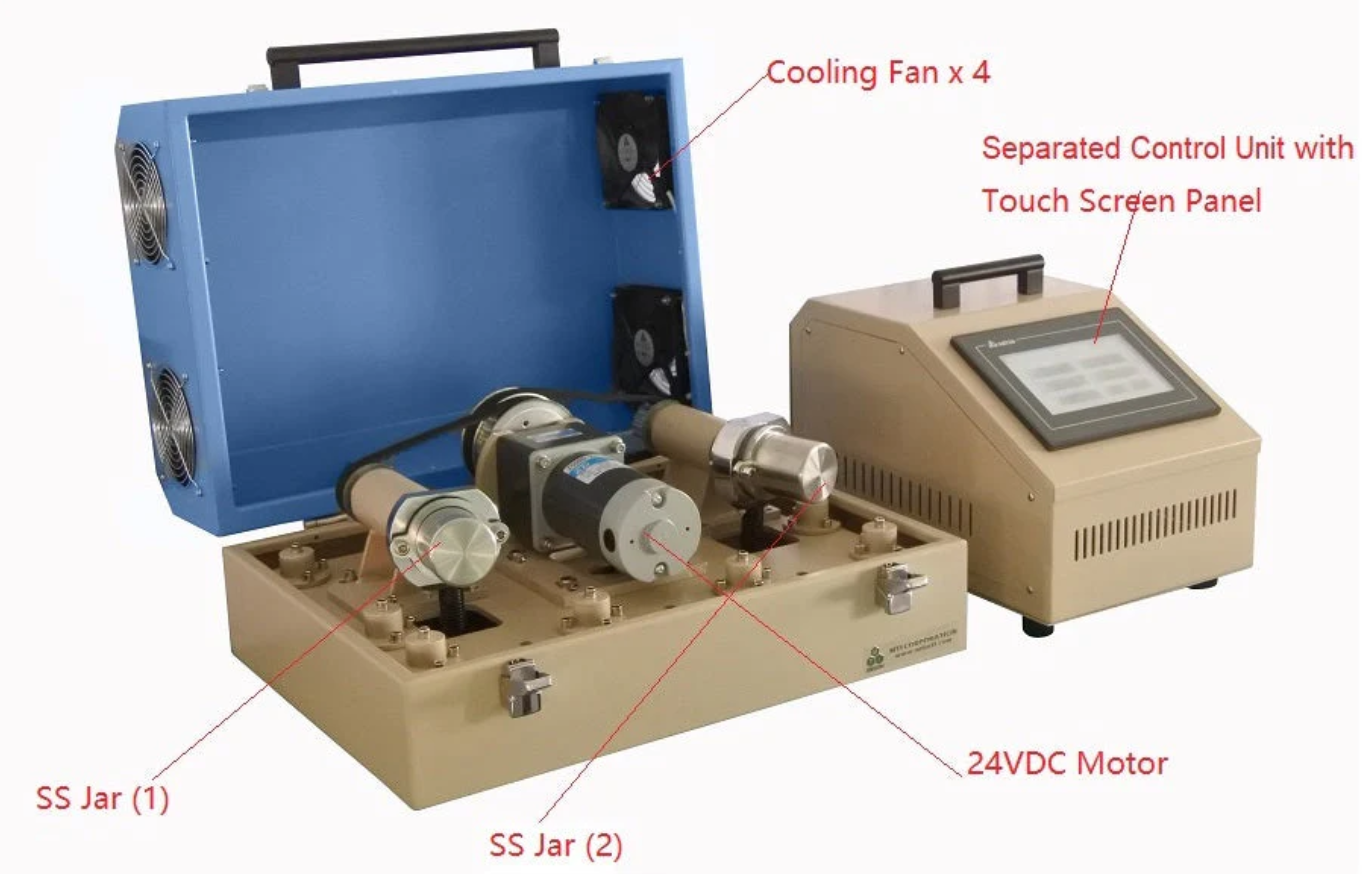

Role of the MSK-SFM-3-II Ball Milling Machine

The MSK-SFM-3-II ball milling machine (MTI Corporation https://mtixtl.com/en-euea/products/msk-sfm-3-ii?_pos=1&_sid=62b9f4eab&_ss=r ) played a critical role in the material preparation process. After synthesizing the initial ingots from high-purity Ge, Sb, Ag, In, and Te by melting and quenching, the solid ingots were mechanically ground using this ball mill. The ball milling was performed at 1000 rpm for 20 minutes, this step was critical:

- Reducing particle size for better sintering,

- Breaking agglomerates to ensure uniform dispersion,

- Promoting chemical homogeneity across the powder,

- Creating a fine microstructure ideal for spark plasma sintering (SPS).

By enabling precise and reliable powder preparation, the MSK-SFM-3-II directly contributed to achieving phase-transition control and record-high thermoelectric performance.

Specifications of the MSK-SFM-3-II

Milling Jars & Balls

- Two 80 ml nylon jars with zirconia milling balls

- Two 80 ml stainless steel jars with SS milling balls

- Optional jars (WC jars, alumina jars, ZrO2 jars) and balls are available.

Control Unit

- A separated control box for operation in a glove box

- Speed control: 300 – 1000 rpm adjustable

- Time control: 0 – 30 minutes adjustable

- Estimated acceleration gravity: ~ 50G

Granularity

- Feeding Granularity: <1mm

- Discharging Granularity: D50 0.1 micron minimum.

Cooling System

- Conditional air cooling is available upon request.

To learn more about the MSK-SFM-3-II Ball Mill, reach out to us at contact@accessr-energy.eu