Introduction

Molten salt electrolysis (MSE) is an advanced high-temperature electrochemical technology that enables the extraction, refining, and synthesis of materials that are otherwise difficult or energy-intensive to produce. It works by dissolving compounds in molten salt and applying an electric current to drive ions to the electrodes, where selective reduction and oxidation reactions generate products. The molten salt electrolysis furnaces are designed to maintain extreme conditions while ensuring efficient heat transfer, electrical conductivity, and safety. In recent years, MSE furnaces have evolved into multifunctional platforms for modern materials research, from clean metallurgy to energy conversion and functional materials synthesis.

Applications for Modern Materials Research

Molten salt electrolysis furnaces are not limited to traditional metal extraction. They play a crucial role across advanced materials science and clean energy research:

1) Extraction of Reactive and Refractory Metals

- For Ti, Zr, Hf, Nb, Ta, and W production.

2) Synthesis of Functional Ceramics and Composites

- Electrochemical fabrication of carbides (TiC, SiC), nitrides (TiN) and borides (ZrB₂).

3) Energy and Nuclear Applications

- High-temperature electrolysis of CO₂ and H₂O to produce CO and H₂ (green fuels).

- Pyro processing of spent nuclear fuel for U, Pu recovery.

- High-temperature electrodes for molten-salt batteries.

4) Surface Engineering and Coating

- Electroplating of dense, corrosion-resistant coatings (e.g., Ni–Al, Cr, Mo).

Advantages of Molten Salt Electrolysis Furnaces

High-temperature stability: Allows electrolysis of refractory compounds and stable ionic conductivity.

Material versatility: Applicable to metals, alloys, ceramics, and composite materials.

High purity of products: Minimal contamination and controllable electrochemical environment.

Environmental compatibility: Avoids carbon-based reduction and reduces CO₂ emissions.

Outlook

With the growing demand for sustainable metallurgy and advanced functional materials, molten salt electrolysis furnaces are poised to become a cornerstone of next-generation materials synthesis.

Molten Salts Electrolysis Reactor from MTI

1000°C Molten Salt Reactor with Three-electrode System – VBF-MS

- Heating Rate: 10 °C/min (20 °C /min)

- Vessel size: Ø76 × Ø70 × 300 mm

- Heating Area: Ø120 ID × 200 H mm

- Temperature depends on vessel materials

- Temperature stability ± 1°C

1200°C Top-loading Furnace for Molten Salt Cell or Electrolysis – VBF-1200S-MS

- Temperature: 1200 °C

- Heating Rate: 20 °C /min Max.

- Reaction Chamber: Quartz, 100 OD x 94 ID x 250 L (mm), Capacity: 1.7 L

- Three copper electrodes: Ф2.38 mm

- Copper connectors for any electrode

- Digital temperature controller: Accuracy ±1°C. 30 segments.

1200°C Max. Molten Salts Reactor with Lifting Mechanism for Electrolysis Refining – VEF-1200

- Working temperature: 1200℃ 1100 °C continuous.

- Heating rate: 20℃/min Max.

- Heating Zone: Ф240 x 245mm (11 Litter)

- Pressure: < 3 psi

- Vacuum chamber: Ф200 * 425mm made of quartz

- Temperature controller: Accuracy ±1°C. 50 segments.

1600°C Molten Salt Electrolytic Furnace – VEF-1600L

- Temperature: 1600 °C

- Chamber size: 410 mm x 410 x 500 mm, 80 Liter

- Two electrodes: Ф20 mm. Made of copper and solid graphite. With cooling jacket

- Water chiller: 16L/minute flow.

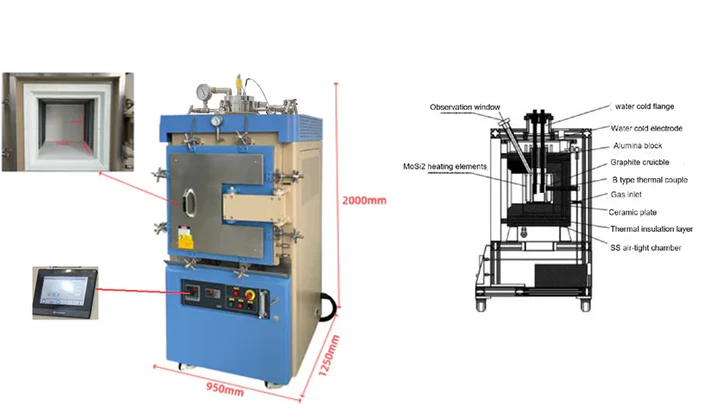

1700°C Molten Salt Electrolytic Furnace – VEF1700

- working temperature: 1300 °C by SiC or 1700 °C by MoSi2

- Temperature Accuracy: +/- 0.5 °C

- Chamber size: 200 x 200 x 200 mm, 8 Liter

- Built-in water cold flanges with a quick clamp

- Recirculating water chiller:16L/minute flow

- Atmosphere-controlled for oxygen, inert gas, and vacuum

- Vacuum pump: 156L/minute speed

For more information, please contact contact@accessr-energy.eu