High-Temperature Materials Testing System with Small Punch Technology

Small Punch Testing (SPT) is a miniature specimen testing technique developed to evaluate the mechanical behavior of materials when only a limited amount of material is available. The method is particularly valuable for high-temperature applications, in-service component assessment, and advanced materials research.

Principle of Small Punch Testing

In a Small Punch Test, a thin disc sample is rigidly clamped between upper and lower fixture. A hemispherical or cylindrical punch applies load at the center of the sample. Depending on the test objective, the load may be applied under displacement control or maintained at a constant level for creep testing. During the test, key parameters such as load, displacement, temperature, and time are continuously recorded. The resulting load–displacement curves provide valuable insight into elastic-plastic deformation, fracture behavior, ductility, and creep properties.

Key Advantages of Small Punch Testing

Small Punch Testing offers several distinct advantages over traditional mechanical testing methods:

- Minimal Material Requirement

The use of miniature specimens allows mechanical characterization when material availability is extremely limited, such as irradiated materials, in-service components, or costly alloys.

- Suitability for High-Temperature Applications

SPT can be performed under controlled high-temperature environments, making it ideal for evaluating materials used in nuclear, aerospace, and energy systems.

- Local Property Evaluation

The small specimen size enables testing of localized regions, including welds, heat-affected zones, and material gradients.

- Reduced Testing Time and Cost

Compared to conventional creep and fracture tests, SPT often requires shorter testing durations and lower operational costs.

Application Areas of Small Punch Testing Technology

Due to its unique capability to evaluate mechanical properties using miniature specimens, Small Punch Testing (SPT) has been widely adopted across multiple industries.

- Nuclear Energy and Irradiated Materials

- Aerospace and High-Temperature Engineering

- In-Service and Remaining Life Assessment

- Welds and Heat-Affected Zones

- Failure Analysis and Degradation Studies

By combining experimental efficiency with strong correlation to standard mechanical properties, High Temperature Small Punch Testing has become an increasingly important tool for modern materials evaluation and remaining life assessment.

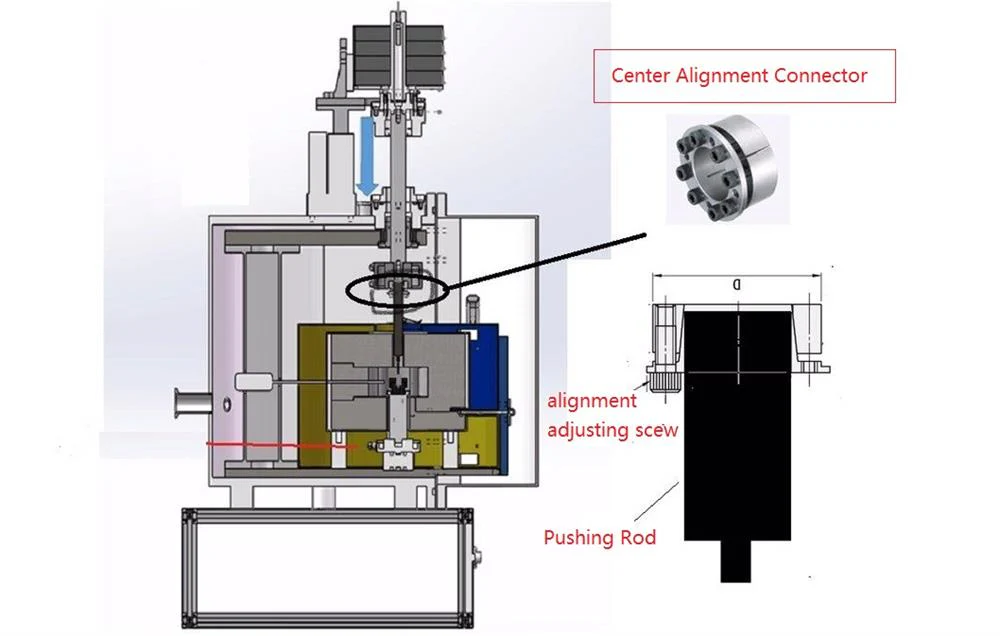

1350°C Max. High Temperature Small Pouch Tester up to 2GPa – OTF-1500X-S-ST

Punch Die Fixture: Made of recrystallized SiC. Tightened by M18x2

Sample dimensions: 8 mm dia. x 0.5 mm thickness

Pushing Rod: made of Moly via precision machining

Max. working Temperature: 1350°C continuously

Vacuum-sealed chamber with a hinged-type door

Vacuum level: 10-2 torr by a mechanical pump and 10-5 torr by a turbopump

Working gas: All types of inert gases and oxygen gas

Software included for parameters setting and results display

For more information, please contact contact@accessr-energy.eu