Ultrasound testing method is nondestructive characterization method for obtaining information about the state of a battery in a fast and non-expensive way. Among the applications of ultrasound are electrolyte wetting, gas formation, Li plating etc.

|

UBSC-LD50 : Ultrasonic Scanning System

|

UBSC-DTBT: Desktop ultrasonic scanning system

|

Main text:

Gas formation, lithium plating, bad electrolyte wetting are important issues to target for safer and more reliable lithium-ion batteries. The nondestructive analyzing techniques are the pivotal tools to estimate the state of an already prepared battery. One of such analyzing techniques is ultrasound testing.

Ultrasonic waves have different propagation speed in different mediums. These differences in propagation speed make it possible to use ultrasound as a non-destructive technique for battery characterization. High frequency ultrasound, focused scanning coupled up with AI tools could help analyze battery conditions.

The applications of the ultrasound testing:

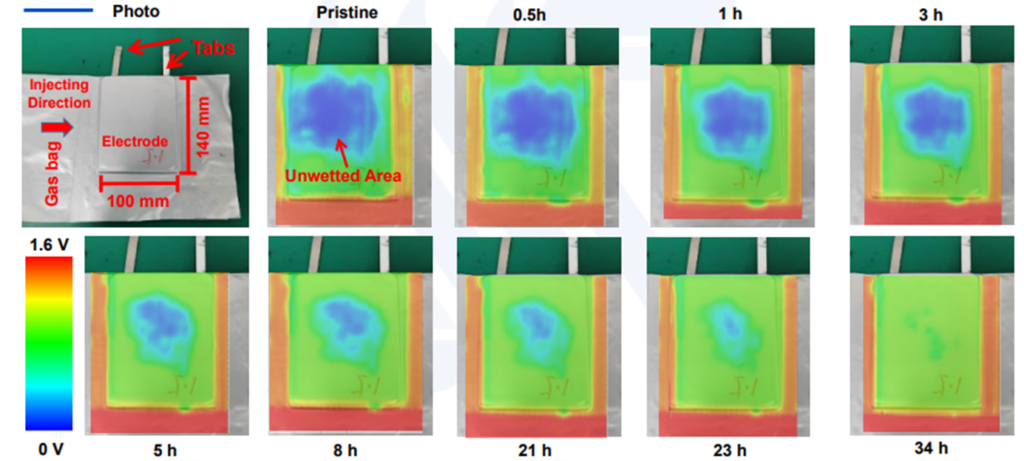

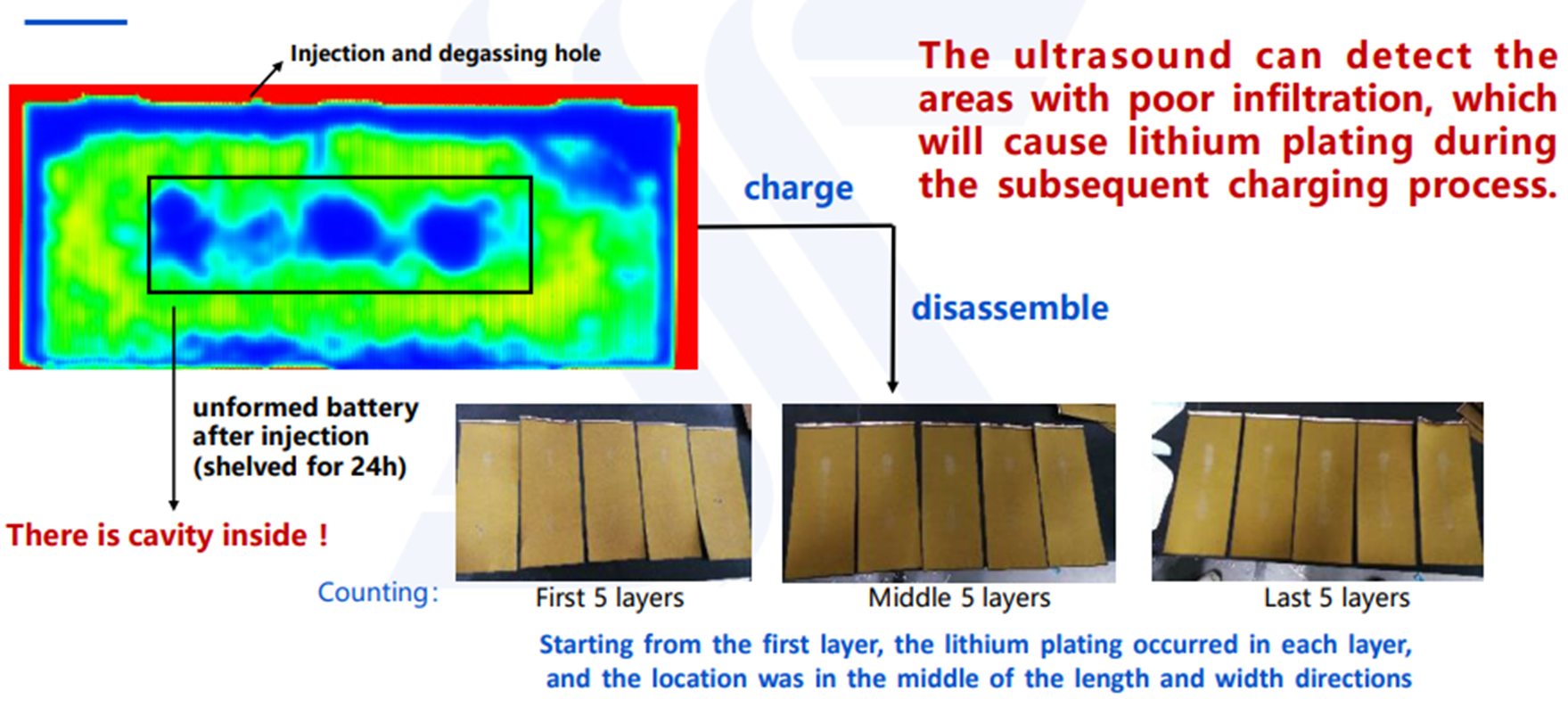

- Electrolyte wetting

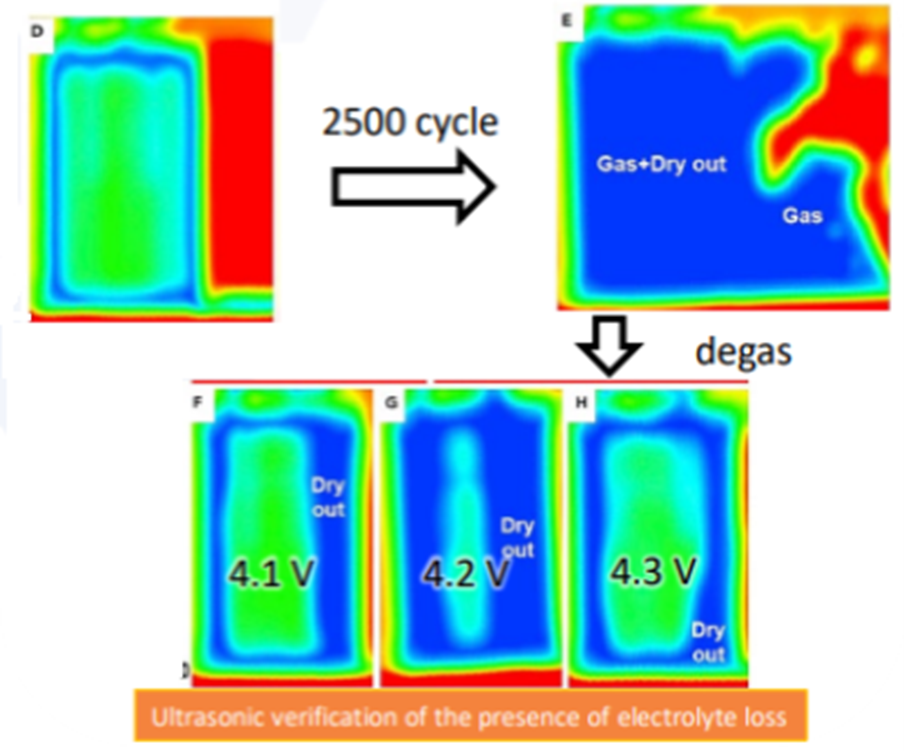

2. Early-stage gassing or leak detection

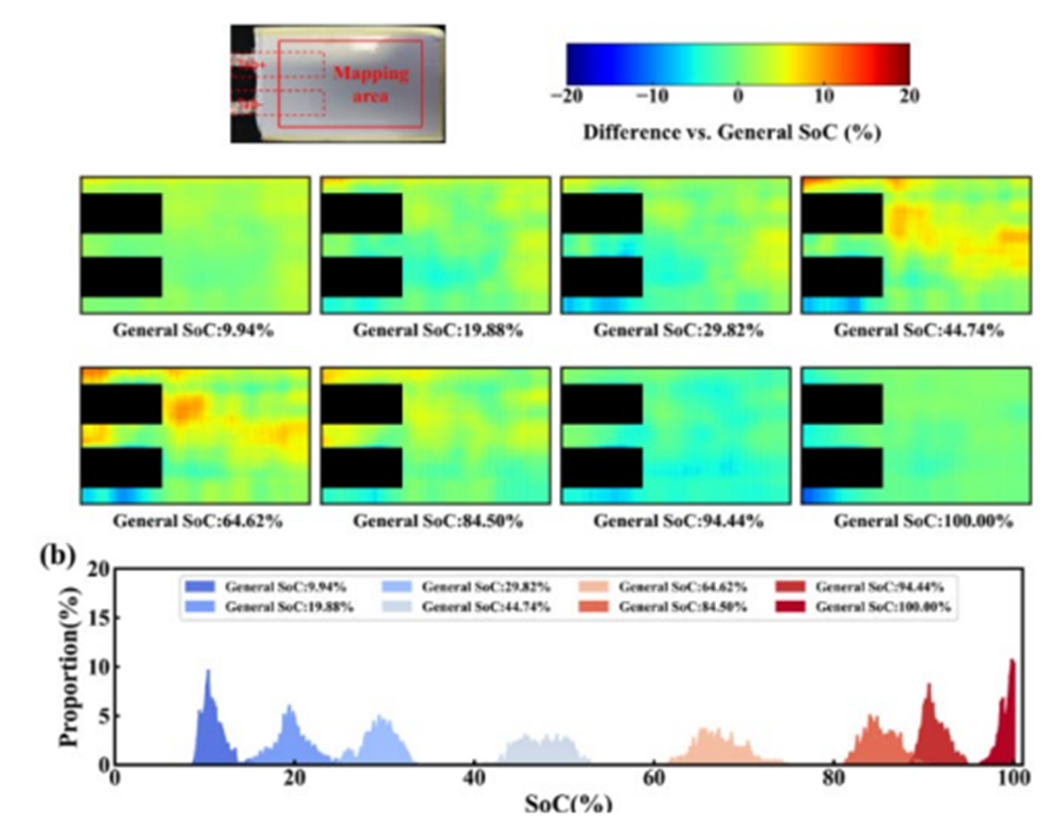

3. SOC monitoring

4. Lithium plating

SPECIFICATIONS UBSC-LD50

|

Features |

|

|

Voltage & Power |

|

|

Applicable Cell-type |

|

|

Coupling Medium |

|

|

Scanning |

|

|

Testing Working Temperature |

|

|

Ultrasonic Transducers |

|

|

Scanning Stage |

|

|

Software |

|

SPECIFICATIONS UBSC-DTBT

|

Feature |

|

|

Voltage & Power |

|

|

Scanning Accuracy |

|

|

Repeated Emission |

|

|

Pulse Width |

|

|

Damping |

|

|

Gain |

|

|

Fitering |

|

|

Scanning Speed |

|

|

Scanning Range |

|

|

Temperature Control |

|

|

Sampling Rate |

|

|

Interface |

|

|

Storage |

|

|

Testing Type |

|

|

Coupling Condition |

|

|

Software |

|