Artificial intelligence (AI) is increasingly transforming the landscape of materials science research. Through the integration of robotic systems and programmable instrumentation, laboratories can streamline complex tasks such as synthesis, characterization, and data acquisition. This enhances experimental efficiency while significantly improving reproducibility and consistency. The ability to operate continuously and generate large volumes of data also supports data-driven approaches, including machine learning and high-throughput screening. Acquired data can help researches use AI tools to predict material characteristics, treatment parameters or even discover new materials. As AI-friendly automation technologies advance, they are becoming an essential component of modern materials research infrastructure.

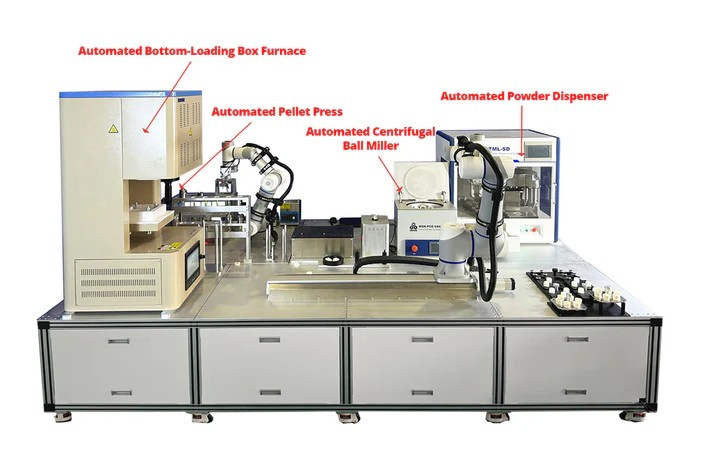

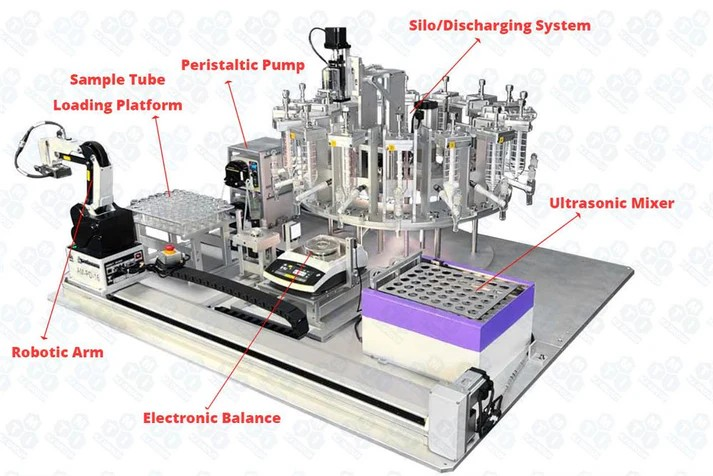

AMSP02 is an Autonomous Platform for Solid-State Material Synthesis.

It is an advanced materials workstation designed to automate the complete processing chain, from raw material weighing and mixing to forming and sintering, according to user-defined experimental protocols. It significantly reduces manual handling, thereby improving process accuracy, reproducibility, and operational efficiency.

This station consists of 4 automated units:

- Automated Powder Dispensing

- Up to 15 powder materials can be dispensed into 6 containers in custom ratios

- Balance Range: 20 mg to 13,000 mg

- Material Container Volume: 450 mL (each)

- Automated Centrifugal Ball Milling/Mixing

- Number of stations: 6

- Ball Mill Jar Dimensions: Ø20 mm × 25 mm (H)

- Maximum Rotation Speed: 2,000 rpm

- Maximum Centrifugal Acceleration: 438 g

- Automated Pellet Pressing

- Automatic Loading, Die Assembly, Pressing, and Ejection

- Maximum Hydraulic Pressure: 24 T

- 12 Sets of Dies with Φ10 mm Core Size (Customizable at Extra Cost)

- Maximum Mold Pressure Capacity: 3,000 MPa

- Automated Bottom-Loading Box Furnace

- Maximum Operating Temperature: 1,700 °C (<1 Hour)

- Continuous Operating Temperature: 1,600 °C

- Chamber Dimensions: 200 × 200 × 200 mm

- Chamber Volume: 8 L

- Constant Temperature Zone: 150 × 150 × 150 mm (±5 °C)

Product link: Autonomous Platform for Solid-State Material Synthesis – AMSP02 – MTI Online Store

Operational video:

MSK-BPE-MS Lab-Scale Automatic Multiple-Layers Pouch Cell Assemble Line for Battery R&D.

It is a laboratory-scale automated assembly line designed for multi-layer pouch cell fabrication. It enables full automation from electrode stacking through electrolyte filling to final cell sealing. The integrated enclosure, connected to a dehumidification system, maintains an ultra-low dew point of -50 °C, ensuring a controlled environment suitable for moisture-sensitive electrodes and electrolytes.

The system consists of multiple automated units:

- Stacker (MSK-111A-RPS)

- Taping Machine (MSK-123-RCS)

- Welder (MSK-UW-R2000W)

- Top/Side Sealer (MSK-140-RSS)

- Automatic Electrolyte Filling and Vacuum sealing Machine (MSK-113-RPS)

- Glovebox or dryroom are optional

Product link: Lab-Scale Automatic Multiple-Layers Pouch Cell Assemble Line for Batte – MTI Online Store

AM-YLJ-8T – Automated Pellet Pressing System up to 6 sample and 8 ton.

It is a compact, glovebox-compatible automated pellet pressing system engineered for high-throughput and autonomous experimentation in the condensed phase. It features programmable operation via an integrated LCD touchscreen and supports precise, rapid pelletization of various powder materials. Its modular design accommodates up to six samples per batch and can operate independently or integrate seamlessly with MTI’s automated materials preparation systems. Included software facilitates instrument control and data acquisition, enhancing system interoperability and workflow automation. The maximum pressure is 1000 MPa and 8 ton force.

Product link: Automated Pellet Pressing System up to 6 sample and 8 ton – AM-YLJ-8T – MTI Online Store

Operational video :

AM-24T-12 – Automatically Pellet Pressing System.

It is an automatic pellet pressing system operated by a remote PC and a build-in robotic arm. It can press 12 pellets of 10 mm diameter autonomously within 2 hours. Maximum pressure is 3000 MPa.

Product link: Automatically Pellet Pressing System (12 set Dies up to 24T) – AM-24T- – MTI Online Store

Operational video :

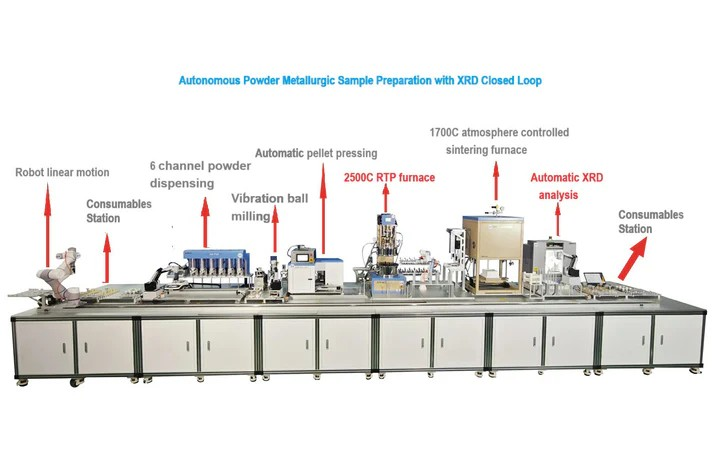

AMPS01 – Autonomous Platform for Powder Metallurgic Sample Preparation with XRD Closed Loop.

The Autonomous Platform for Powder Metallurgical Sample Preparation with XRD Closed Loop is an integrated system designed to automate the preparation and analysis of powder metallurgical samples. By reducing manual handling, it enhances precision, repeatability, and efficiency. A real-time closed-loop feedback mechanism with X-ray Diffraction (XRD) monitors sample composition and quality, adjusting processing parameters to ensure optimal results. Ideal for high-throughput labs and applications requiring strict quality control, the system delivers consistent preparation, minimized human error, and reliable analytical performance.

The system consists of multiple automated units that can be selected by client. Example below:

- XRD analytical system

- Sintering furnace

- RTP furnace

- Vibration ball milling

- 6 channel powder dispensing system

- Robotic arm

Product link: Autonomous Platform for Powder Metallurgic Sample Preparation with XRD – MTI Online Store

Operational video :

KSL‑1200X‑M‑AD

is an automated, high-temperature box furnace with the maximum temperature up to 1200 °C. It features multiple automated operations such as door opening/closing, raising the temperature, dwelling, and cooling. Making it ideal for repetitive, high-throughput material treatments.

Main Features:

- Max Temperature: 1200 °C (short-duration); 1100 °C continuous operation

- Heating Chamber: 300 × 300 × 300 mm ceramic-insulated volume (~27 L)

- Heating Rate: ≤10 °C/min with uniform center zone (150 mm cube, ±5 °C)

- Control System: PID, 30-segment programmable via included PC & software;

- Automation: closing/opening door, heating, dwelling, cooling; optional robotic integration for loading/unloading

Product link: https://mtixtl.com/products/ksl-1200x-m-ad

Operational video :

AM-PD16

is a compact, glovebox-compatible powder dispenser designed for high-throughput material experiments. Easily programmable via touchscreen, it handles up to 16 samples per run, dispensing powders up to 100 g with ±1 mg accuracy.

Main Features:

- 16-channel dispensing

- Fully automated sequential dispensing

- Feeding capacity from 10 mg to 100 g

- Feeding accuracy 1 mg

- Glovebox compatible

- Touchscreen programmable

Product link: Automated 16-channel Powder Dispensing System- AM-PD16 – MTI Online Store

Operational video: